MEET THRIVE

Software for the Shop Floor

Your Data. Organized. Visible. Actionable

IS YOUR SHOP FLOOR SUFFERING FROM…

Spreadsheet Chaos?

Tired of broken links and difficult reporting?

ERP Pain?

The ERP said it could, but it can’t.

Broken Workflows?

Bouncing between five systems to

execute one simple task?

IS YOUR SHOP FLOOR SUFFERING FROM…

Spreadsheet Chaos?

Tired of broken links and difficult reporting?

ERP Pain?

The ERP said it could, but it can’t.

Broken Workflows?

Bouncing between five systems to

execute one simple task?

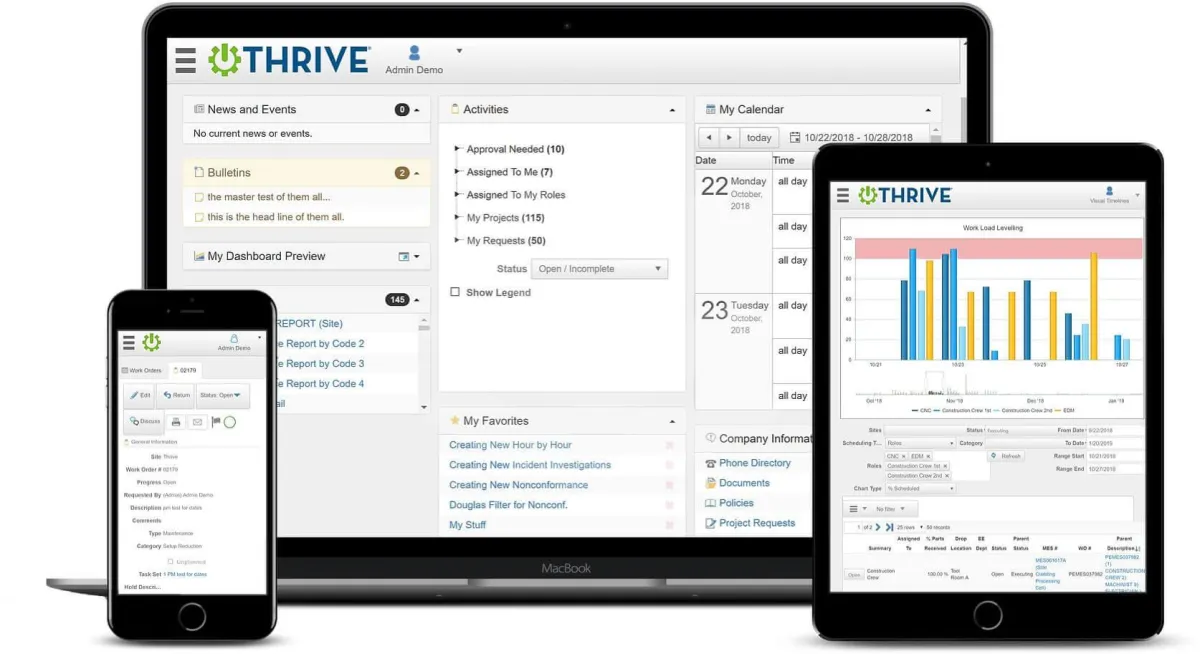

What is Thrive?

Thrive is your complete shopfloor toolbox comprised of functional-area modules that seamlessly link to one another in one cohesive platform. Use one module or all of them. Personalize the modules to your specific needs and unique processes.

Thrive Overview

The Thrive Difference.

Thrive Organization

Central hub for all shopfloor data

Designed to give clarity to your data collection and processes

Track all actions, tasks, projects, communication, and goals in one place

Thrive Visability

Web-based, mobile-friendly

Sharable real-time reports and action items

Personalized dashboards and communication tools

ERP and machine integration

Thrive Accountability

Streamline projects and improvement goals

Built in escalation tool with oversight to workflow

Action item notifications

Scheduling tools

The Thrive Difference.

Thrive Organization

Central hub for all shopfloor data

Designed to give clarity to your data collection and processes

Track all actions, tasks, projects, communication, and goals in one place

Thrive Visability

Web-based, mobile-friendly

Sharable real-time reports and action items

Personalized dashboards and communication tools

ERP and machine integration

Thrive Accountability

Streamline projects and improvement goals

Built in escalation tool with oversight to workflow

Action item notifications

Scheduling tools

We know manufacturing because we’ve lived manufacturing.

Lean Technologies brings together a group of manufacturing operations folks who know manufacturing pains — firsthand — and they have developed a solution to those pains and a solution that will help you gain. They called that solution Thrive, and it’s what they want to see your manufacturing operations do.

They Thrive. Find Out Why.

Your software shouldn’t limit your best possible process.

We align Thrive to your best processes and eliminate waste.

Make a Plan for Your Business to Thrive.

1: Schedule a Call

In under 15 minutes we can learn if Thrive is in the same neighborhood as your goals.

2: Demo

See Thrive for yourself. Invite your team. Brainstorm the possibilities.

3: Define the Plan

Together come up with a roll-out plan to leverage the parts of Thrive that will give you immediate wins.

4: Start to Thrive

Roll-out Thrive in a matter of days/weeks. Begin to experience simplified data management on your shopfloor.

Power Your Operations with Thrive

Thrive is your all-in-one tool that will keep you, your team, and your entire organization on the same page, accessing the same data and effectively communicating — for process, productivity and profit. Thrive is more than a lean manufacturing tool — its easy-to-use and sharable reports, its goal-setting features, and its oversight to productivity and profits helps your manufacturing plant to THRIVE.

Thrive Pricing

We think pricing should be simple, straightforward and right out in the open. If you have questions, just ask us.

Thrive Module Hosted

$600

monthly

Cloud Hosted

ONE Module

Unlimited Users

All updates/version upgrades

All Thrive features/tools included

On-site/virtual training – OPTIONAL (quote)

Data transfer/conversion – OPTIONAL (quote)

ERP integration – OPTIONAL (quote)

Annual Support Contract included in Thrive Hosted price

Thrive Connected Hosted

$950

monthly, billed annually

Cloud Hosted

ALL Modules Included

Unlimited Users

All updates/version upgrades

All Thrive features/tools included

On-site/virtual training – OPTIONAL (quote)

Data transfer/conversion – OPTIONAL (quote)

ERP integration – OPTIONAL (quote)

Annual Support Contract included in Thrive Hosted price

Thrive

On-Premise

$40,000

one-time

ALL Modules Included

On-Premise Install

Unlimited Users

All updates/version upgrades

All Thrive features/tools included

On-site/virtual training – OPTIONAL (quote)

Data transfer/conversion – OPTIONAL (quote)

ERP integration – OPTIONAL (quote)

Annual Support Contract – 15% of current Thrive price

Think of Thrive as your tool and Lean Technologies as your partner.

Think of Thrive as your tool and Lean Technologies as your partner.

"Our IT loved working with Thrive!"

"- Beth Wilkerson, Compliance Manager, Specialty Manufacturing

"We have the real-time data for effective daily problem-solving"

- Pete Barboni, Intek Plastics

From Manual Chaos to Connected Excellence — How ASSA ABLOY Scaled Lean Manufacturing with Thrive

"We went from sticky notes and walking back and forth… to seeing everything on one screen." — Sergio, Engineering & CI Lead

Norton Modernization

"Easy integration with our systems" - Antonio Ancrum

Get Ready to Thrive

Get Ready to Thrive

LEAN TECHNOLOGIES

427 Main Street

Pella, IA 50219

866-LEAN-TEC (866 532-6832)

For Technical Support: [email protected]

ABOUT US | CONTACT US | VIDEOS | THRIVE RESOURCES | FAQ | CAREERS | BLOG | PRIVACY POLICY | TERMS OF SERVICE.

© Copyright 2026. Thrive by Lean Technologies. All rights reserved.